Custom Webbing: A Guide to Selecting the Right Material For Cargo Control

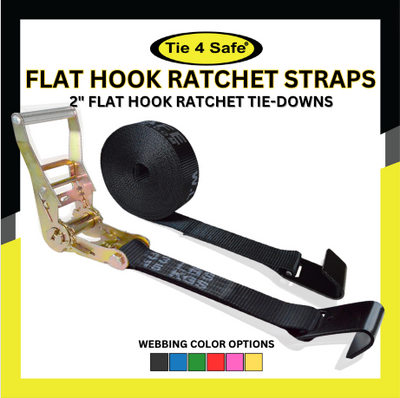

In the dynamic world of cargo control, the choice of webbing material can make all the difference in ensuring the safe and secure transport of goods. From heavy machinery to fragile equipment, selecting the appropriate webbing is essential for safeguarding cargo during transit. In this blog post, we'll delve into the concepts of webbing breaking strength and working load limits, explore different types of webbing materials, and provide insights on how to choose the best webbing type for cargo control.

understanding

Webbing Breaking Strength and Working Load Limits

Exploring

Different Types of Webbing Materials

Selecting the best

the Best Webbing Type for Cargo Control

Custom webbing solutions are essential for cargo control, providing tailored strength, durability, and versatility to meet the diverse needs of various industries. By understanding webbing breaking strength, working load limits, and the different types of materials available, transportation professionals can make informed decisions when selecting the best webbing type for their specific applications. Whether securing heavy machinery, delicate equipment, or everyday cargo, investing in high-quality custom webbing ensures safe and efficient transport, enhancing reliability and peace of mind for drivers, shippers, and receivers alike.